- Sheetcam tutorial portable#

- Sheetcam tutorial pro#

- Sheetcam tutorial software#

- Sheetcam tutorial crack#

The subsequent parameterization of a cutting process also takes place in a few easy-to-remember steps for an operator, directly at a machine, in the simCNC control software, using the built-in parameter table. There is no tutorial for JUST plasma cutting but one aimed at vinyl cutting would have a lot of the same issues.

Sheetcam tutorial portable#

This Gcode has no cutting parameters, which is a desirable feature because it is portable from machine to machine and between different types of cut sheet metal. Thanks to this software, even an inexperienced operator is able to generate a gcode in a few easy-to-remember steps in just several dozen seconds. You will see your new layers in the layer pane shown here. Right clock on the gear teeth and create a new layer called 'Teeth'. In the small dialog box, give the layer the name of 'shaft hole' as shown here.

Select the Move to layer/New layer option shown here.

Sheetcam tutorial software#

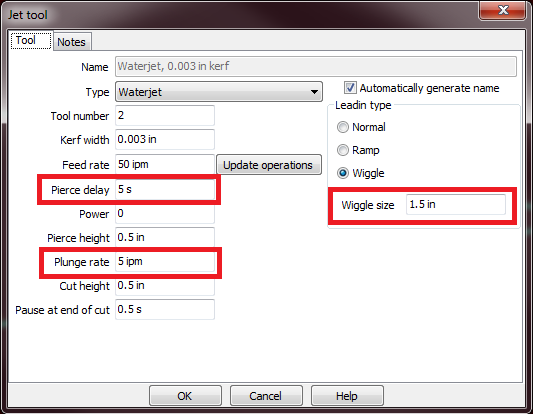

The CAM software that fits perfectly in this role due to its simplicity, functionality and price is the SheetCAM software. Right click on the gears shaft hole shown here. SheetCam has already loaded the same tool settings as the last tutorial so we can get. Consequently, CAM software has only become a trajectory generator, i.e. SheetCam accepts data in the form of DXF files (CAD drawings).

Sheetcam tutorial crack#

Preg Crack 2021 is a great utilitg that helps us trace our stolen. SheetCam T NG Development V6.1.37.rarSheetCam T NG Development vs. SheetCam is a law cast but Feature packed CRM package.

Sheetcam tutorial pro#

All possible parameterization of a cutting process has been handed over to an operator and software controlling a plasma cutter. 1 Free Dawnlaad Latest Version Logic Pro VST Crack (Mac) Free. Over the past few years, the way of organizing work between CAM software> operator> plasma cutter has changed significantly. SheetCam is suitable for plasma, milling, routing, waterjet, laser and oxy-fuel cutting. We're happy to discuss what software may work best for your project.SheetCam is a low cost but feature packed CAM package. There are other free/open-source packages for all these areas.įor more information on the software paths you can take to go from idea, to design, to finished project, please see our CAD/CAM Toolchain page. V-Carve Pro can also be installed on your own computer, but the final output is via the version installed on our computers. The links to the plasma and mill post processors for m圜NC from SheetCam have been added to the Downloads page of the website. A number of programs can be installed on your personal computers, such as Fusion 360, Inkscape, etc. *Not every package is installed on every workstation. Graphic/Vector Art: Inkscape (free/open-source, class), Corel Draw, Adobe IllustratorĬAD: Fusion 360 (3D, often free, class), Geomagic Design (3D, tutorial), SolidWorks (3D)ĬAM: Fusion 360 CAM (2D, 3D, often free, class, tutorial), V-Carve Pro Makerspace Edition (2D, 3D, free for members, class), SheetCam (2D, tutorial), MeshCAM Pro (3D, tutorial) Where we don't teach a skill development class for a piece of software, there is often a tutorial we offer. Some are general purpose, and others are very machine-specific. These packages help us program the computer-controlled tools we have in every shop. SheetCAM is widely regarded as the easiest and motion efficient solution available for generating G-code files for CNC Plasma Cutting.

0 kommentar(er)

0 kommentar(er)